|

Zhejiang JinYuan Copper International Co., Ltd.

|

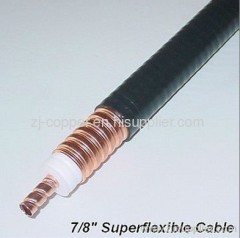

50ohm 7/8"Radio Communication Feeder Cable

| Price: | 0.1 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

50 ohm 7/8" Radio Frequency Communication Feeder Cable for Antenns Feeder System

50 ohm 7/8" Radio Frequency Communication Feeder Cable for Antenns Feeder System

Applications:

50 ohms corrugated copper tube series coaxial cables have wide applications in antenna feeder systems as follows:

1. Land mobile and cellular radio,

2. Earth station antenna jumper cables,

3. Jumpers for equipments room and antenna connection,

4. Military data links,

5. VLF, AM and FM radio broadcast systems,

6. Point to point terrestrial microwave,

7. Airborne and shipboard radar systems,

8. Tactical, restoration and portable communication systems

9. Others.

Advantages:

1. Excellent Electrical performances: 80% super-high degree foaming polyethylene insulation of features with low attenuation and stability in case of temperature variation due to small coefficient of temperature. The insulation of longitudinally homogeneous structure and extra-precisely corrugated copper tube outer conductor characteristic of low VSWR makes the cable your choice even in high-frequency applications.

2. Simple use and complete range: The light, flexible and easily-bending thin-wall corrugated copper conductor offers convenience for terminal work. With totally 6 types in terms of dimensions, Hansen can provide the customer with exceptionally super-flexible kind(say 1/2? S) per their requirements.

3. Ease of maintenance: The special structure of high-degree physical foaming PE insulation and corrugated copper tube outer conductor presents premises for effective moisture-proofing even without injection of drying-gases, thus assuring performances stability in terms of long period.

Specifications:

Inner conductor: Smooth Copper Tube

Diameter (mm): 9. 00+- 0. 10

Insulation: Three layers of insulation

Diameter (mm) 22. 0+- 0. 5

Outer conductor: Corrugated copper tube

Diameter over copper

Outer conductor (mm): 24. 94+-0. 30

Diameter over trough (mm): 21. 60+-0. 30

Pitch (mm): 3. 00+-0. 30

Jacket:

Thickness (mm): 1. 3+-0. 2

Diameter (mm): 27. 6+-0. 2

Engineering data:

Weight (kg/km): 570

Minimum bending radius (mm):

Single bending: 140

Mutiple bending: 280

Temperature range (C): -40 to 70

Electrical performance:

Impedance: 50+ -2

Capacitance (pF/m): 76+ -2

Velocity (% ): 88

DC resistance (20, /km):

Inner conductor: 1. 18

Outer conductor: 1. 20

DC breakdown (V): 6, 000

Peak power rating (kW): 91

Maximum frequency (GHz): 5. 0

Main Export Markets: Worldwide

Primary Competitive Advantages:

Experienced Technical Staff

Product Performance

Prompt Delivery

More details information about follows items, please visit our website:

1. 50 ohm Braiding Low Loss Commuication for Wireless Communication (12D, 8D, 7D, 5D, LMR400, LMR200 and LMR600);

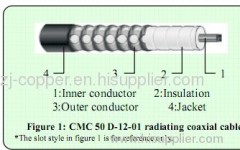

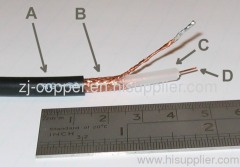

2. 50 ohm Foamed Polyethylene Dielectric Radiating Coaxial Cable for communication(1/2", 7/8", 1-1/4", 1-5/8");

3. 50 ohm Corrugated Copper Tube RF Feeder Cable (1/2", 1/2" Superflexible, 3/8", 3/8" superflexible, 7/8", 7/8" superflexible, 5/8", 1-1/4" and 1-5/8").

Applications:

50 ohms corrugated copper tube series coaxial cables have wide applications in antenna feeder systems as follows:

1. Land mobile and cellular radio,

2. Earth station antenna jumper cables,

3. Jumpers for equipments room and antenna connection,

4. Military data links,

5. VLF, AM and FM radio broadcast systems,

6. Point to point terrestrial microwave,

7. Airborne and shipboard radar systems,

8. Tactical, restoration and portable communication systems

9. Others.

Advantages:

1. Excellent Electrical performances: 80% super-high degree foaming polyethylene insulation of features with low attenuation and stability in case of temperature variation due to small coefficient of temperature. The insulation of longitudinally homogeneous structure and extra-precisely corrugated copper tube outer conductor characteristic of low VSWR makes the cable your choice even in high-frequency applications.

2. Simple use and complete range: The light, flexible and easily-bending thin-wall corrugated copper conductor offers convenience for terminal work. With totally 6 types in terms of dimensions, Hansen can provide the customer with exceptionally super-flexible kind(say 1/2? S) per their requirements.

3. Ease of maintenance: The special structure of high-degree physical foaming PE insulation and corrugated copper tube outer conductor presents premises for effective moisture-proofing even without injection of drying-gases, thus assuring performances stability in terms of long period.

Specifications:

Inner conductor: Smooth Copper Tube

Diameter (mm): 9. 00+- 0. 10

Insulation: Three layers of insulation

Diameter (mm) 22. 0+- 0. 5

Outer conductor: Corrugated copper tube

Diameter over copper

Outer conductor (mm): 24. 94+-0. 30

Diameter over trough (mm): 21. 60+-0. 30

Pitch (mm): 3. 00+-0. 30

Jacket:

Thickness (mm): 1. 3+-0. 2

Diameter (mm): 27. 6+-0. 2

Engineering data:

Weight (kg/km): 570

Minimum bending radius (mm):

Single bending: 140

Mutiple bending: 280

Temperature range (C): -40 to 70

Electrical performance:

Impedance: 50+ -2

Capacitance (pF/m): 76+ -2

Velocity (% ): 88

DC resistance (20, /km):

Inner conductor: 1. 18

Outer conductor: 1. 20

DC breakdown (V): 6, 000

Peak power rating (kW): 91

Maximum frequency (GHz): 5. 0

Main Export Markets: Worldwide

Primary Competitive Advantages:

Experienced Technical Staff

Product Performance

Prompt Delivery

More details information about follows items, please visit our website:

1. 50 ohm Braiding Low Loss Commuication for Wireless Communication (12D, 8D, 7D, 5D, LMR400, LMR200 and LMR600);

2. 50 ohm Foamed Polyethylene Dielectric Radiating Coaxial Cable for communication(1/2", 7/8", 1-1/4", 1-5/8");

3. 50 ohm Corrugated Copper Tube RF Feeder Cable (1/2", 1/2" Superflexible, 3/8", 3/8" superflexible, 7/8", 7/8" superflexible, 5/8", 1-1/4" and 1-5/8").

Specifications - Construction

| Inner Conductor | Copper tube | Φ 9.3 mm |

| Dielectric | Cellular polyethylene | Φ 22.0 mm |

| Outer Conductor | Corrugated copper tube | Φ 25.2 mm |

| Jacketing | Black, halogen-free fire-retardant thermoplastic / Black, halogen-free polyethylene (optional) | Φ 27.8 mm |

| Marking | Trademark, cable type, manufacture week, year, batch number and meter mark | -- |

Specifications - Electrical Characteristics at +20°C

| Characteristic Impedance | 50 ± 1 Ω |

| Return Loss | 24 dB for 100 m cable with connectors |

| Attenuation | See table below |

| Velocity Factor | 0.90 |

| Capacitance | 73.0 pF/m |

| Maximum Frequency | 5100 MHz |

| Max Power Rating | See table below |

| Peak RF Voltage Rating | 3.2 kV |

| Peak Power Rating | 92.0 kW |

| DC resistance | Inner conductor: 1.11 Ω/km, Outer conductor: 1.11 Ω/km |

| Frequency (MHz) | Attenuation (dB/100m) | Power Rating (kW) | Frequency (MHz) | Attenuation (dB/100m) | Power Rating (kW) | |

|---|---|---|---|---|---|---|

| 10 | 0.348 | 27 | 900 | 3.56 | 2.6 | |

| 30 | 0.607 | 15 | 950 | 3.66 | 2.5 | |

| 50 | 0.78 | 12 | 960 | 3.68 | 2.5 | |

| 88 | 1.05 | 8.9 | 1000 | 3.77 | 2.5 | |

| 100 | 1.12 | 8.3 | 1200 | 4.16 | 2.2 | |

| 108 | 1.17 | 8.0 | 1400 | 4.53 | 2.0 | |

| 174 | 1.49 | 6.2 | 1600 | 4.87 | 1.9 | |

| 200 | 1.61 | 5.8 | 1800 | 5.20 | 1.8 | |

| 300 | 1.98 | 4.7 | 1900 | 5.36 | 1.7 | |

| 400 | 2.31 | 4.0 | 2000 | 5.51 | 1.7 | |

| 450 | 2.46 | 3.8 | 2200 | 5.81 | 1.6 | |

| 500 | 2.60 | 3.6 | 2400 | 6.11 | 1.5 | |

| 512 | 2.63 | 3.5 | 2600 | 6.39 | 1.4 | |

| 600 | 2.86 | 3.2 | 2800 | 6.66 | 1.4 | |

| 700 | 3.11 | 3.0 | 3000 | 6.93 | 1.3 | |

| 800 | 3.34 | 2.8 | 3400 | 7.44 | 1.2 | |

| 850 | 3.45 | 2.7 | 4000 | 8.17 | 1.1 | |

| 890 | 3.54 | 2.6 | 5000 | 9.30 | 1.0 |

* Attenuation values are typical at ambient temperature +20°C. Power rating ambient temperature +40°C, inner conductor +100°C.

Specifications - Mechanical Characteristics

| Weight | 0.49 kg/m |

| Maximum Pulling Force | 2800 N |

| Minimum Bending Radius | Single Bending: 120mm, Repeated Bending: 240 mm |

| Operating Temperature Range | -55 ~ +80 °C |

| Crush Resistance | 1.6 kg/mm |

| Bending Moment | 15.0 Nm |

| Recommended Clamp Distance | 1.0 m |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Communication Cable

Feeder Cable

Car Radio Communication

Data Communication Cable

Armored Communication Cable

Multimedia Communication Cable

More>>